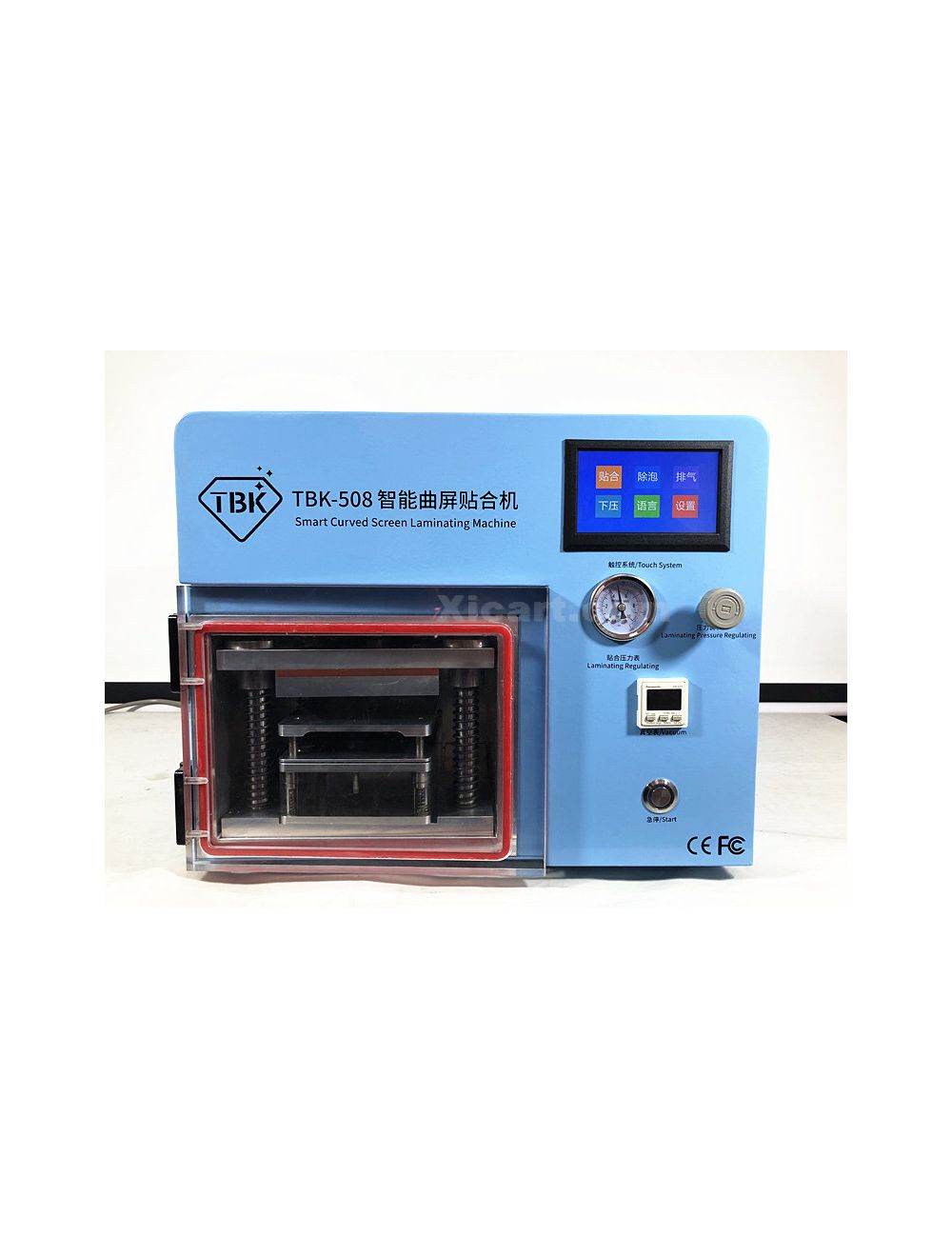

2018 Newest 5 in 1 Vacuum OCA Lamination Machine (With alignment Molds) #TBK-508

PRODUCT DESCRIPTION

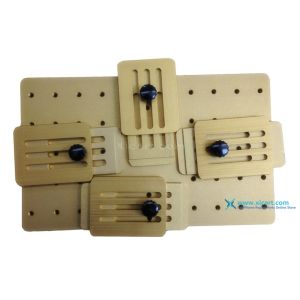

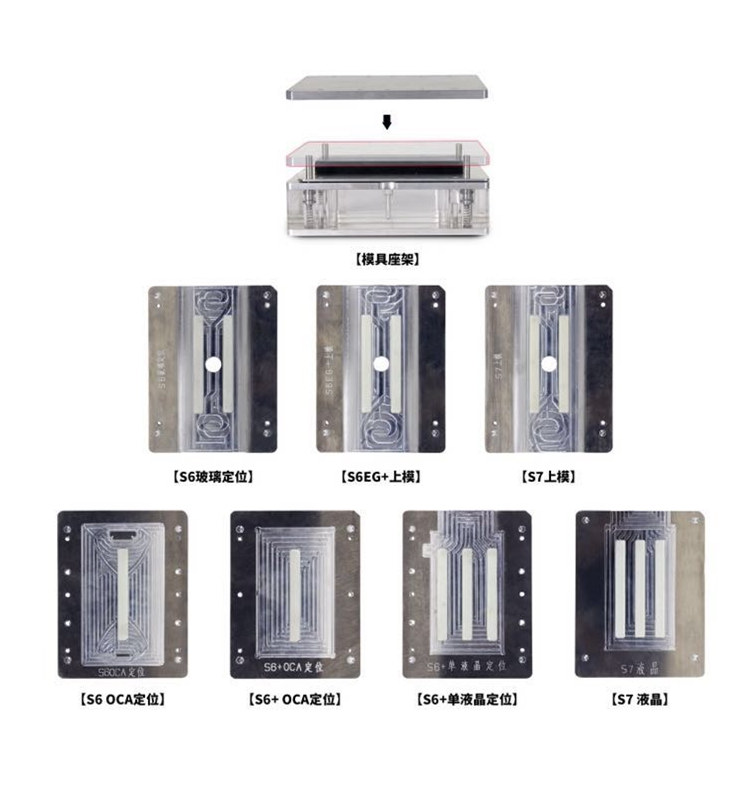

2018 New version 5in1 laminating machine with Alignment molds ↓:

Inlcuded 1pcs base mold and 4 set molds (7inch flat mold, s6 edge mold, s6 edge plus mold, s7 edge mold)

Below is old version without any molds ↓ :

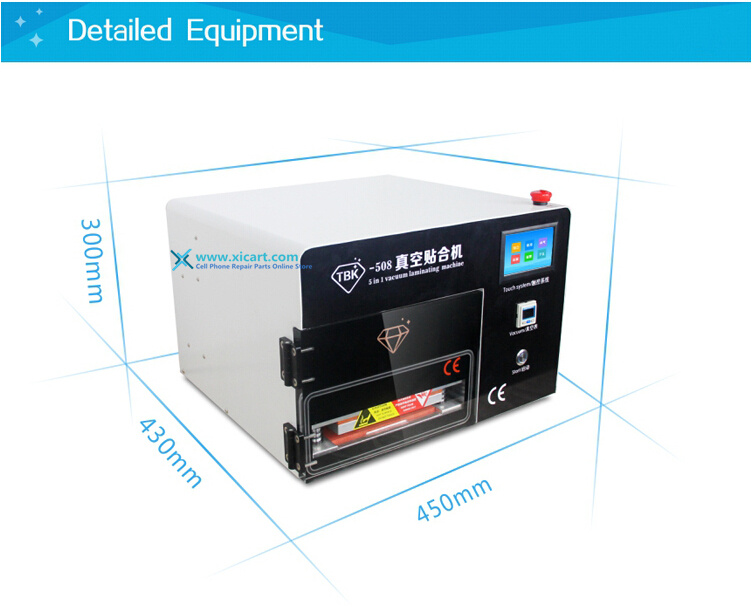

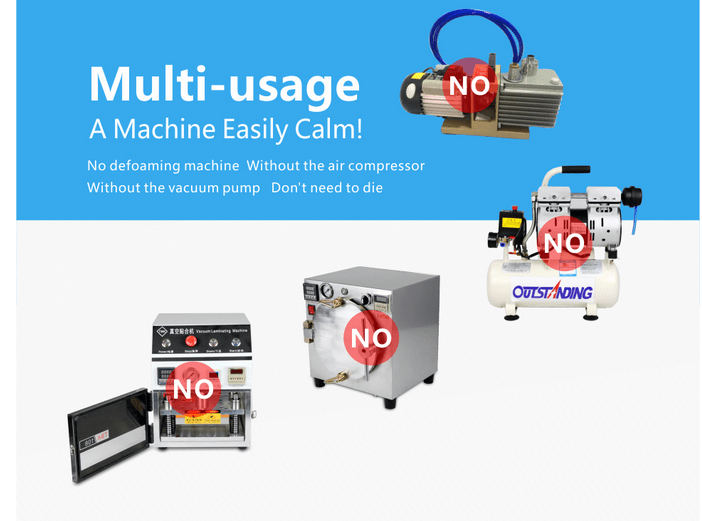

TBK 5 in 1 machine is the newest machine for LCD refurbishing, it has built in vacuum pump and servo motor for laminating (which means it does not need any extra vacuum pump and air-compressor any more), another particular feature is it has a built in autoclave, this autoclave is working for air-bubble removing.

1.New upgrade 5 in 1 vacuum laminating machine with touch system

Adopt advanced constant temperature, constant pressure technology, 100% vacuum effect , no bubbles at all.

2.Laminating dont need moulds,only need use Bakelite mould Alignment screen before put it to machine,Save cost

Using the most advanced pressure principle, Have best laminating effect

3.Built-in Customize oiless vacuum pump, ultra-quiet, long service life

Machine only have 48KG, Passed CE certification,Suit for Europe and USA Market ,Very convenient

4.Super practical intelligent 5 in 1 laminating machine ,Touch system,Multi-functions

Built-in bubble remove machine/air compressor/vacuum pump

Why do you configurate a built-in autoclave for this 5 in 1 machine?

This machine has 2 working model:

Model 1: Set the laminating time 3 minutes

In this model, mostly there is no any air bubble if you install the OCA film on the LCD very well before laminating. so there is no need to use the autoclave for air bubble removing after laminating finished.

Model 2: Set the laminating time 30 seconds only (this model is good for those workshop which need fast refurbishing )

In this model, it will only take 30 seconds to finish the laminating, the refurbishing efficiency is about 120pcs/hour, but it needed the autoclave to remove the air bubbles after laminating finished.

Do i really need this multifunctional machine with built in autoclave for air bubble removing?

Whatever you choose JX0010 or M-T 3 in 1 machine, we promise you will laminate the LCD very well, but if you are not so skillful about OCA film installing, then you might will have the air bubbles on the LCD (especially for those big size screen like 5.5 inches).

But with this machine, you will never worried the LCD laminating no matter you are a green hand or an old hand, because this built in autoclave will remove the air bubbles in case it left on the LCD.

Introduction :

This Latest Vacuum OCA lamination Machine , can be suitable for touch screen Cover plate (Cover Lens) and functional Glass Sensor (Glass) of OCA laminating process;

Apply to the Touch screen (Touch Panel) and liquid crystal module (LCD Panel) of the OCA laminating process,

at the same time can also be applied to other areas of membrane, glass to glass (glass) of hard in hard OCA laminating process.

Features :

* No vacuum pump , No air compressor , No mold, no bubble;

* A key to start, easy to operate;

* Flat lamination way, the overall lamination, smooth uniform pressure,

no stress concentration, no color pattern after lamination, no indentation, LCD chaos color,

smaller convenient transportation.