Instruction Manual For YMJ Laminating Machine

User Manual:

| Laminate OCA | |||

| Air pressure | Temperature | Vacuumize time | Soak time |

| 0.3—0.5Mpa | 45—50℃ | 28—35s | 20—30s |

| Laminate TP | |||

| Air pressure | Temperature | Vacuumize time | Soak time |

| 0.3—0.5Mpa | 45—50℃ | 28—35s | 20—30s |

| Laminate LCD | |||

| Air pressure | Temperature | Vacuumize time | Soak time |

| 0.15—0.2Mpa | 45—50℃ | 28—35s | 15—20s |

|

|

|

|

1 . Switch on the power switch |

2 . Choose auto-pattern (This just take auto-pattern for example , you can also choose manual pattern) |

|

|

|

|

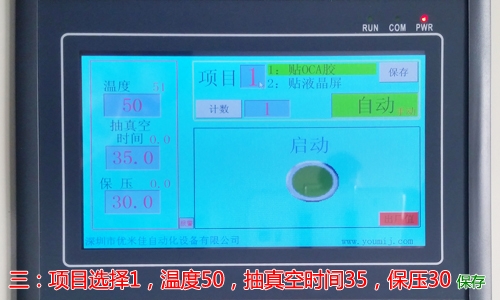

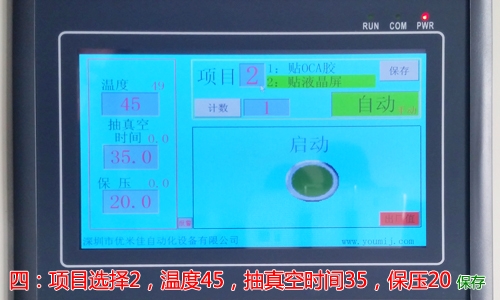

3 . Click items and choose 1 , set temperature to 50 , vacuumize time to 35 , soak time to 30 (save) |

4 . Click items and choose 2 , set temperature to 45 , vacuumize time to 35 , soak time to 20 (save) |

|

|

|

|

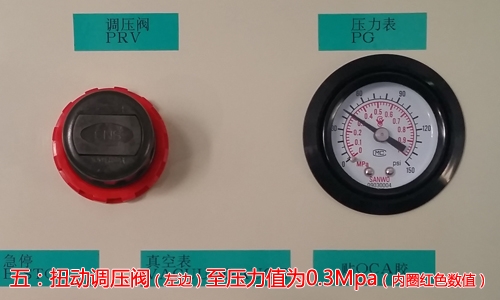

5 . Rotate the left pressure-regulating valve to adjust the pressure value to 0.3 MPa (The red value of inner ring) |

6 . Rotate the right pressure-regulating valve to adjust the pressure value to 0.2 MPa (The red value of inner ring) |

|

|

|

|

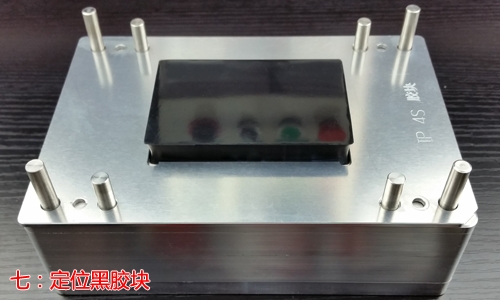

7 . Fix the black gommure |

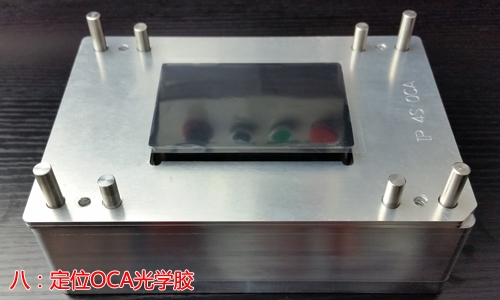

8 . Fix OCA |

|

|

|

|

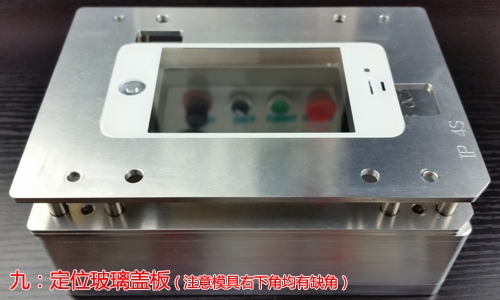

9 . Fix glass (Attention there is an indentation in the lower right of the mould ) |

10 . Push into vacuum chamber and then switch the button of laminating OCA |

|

|

|

|

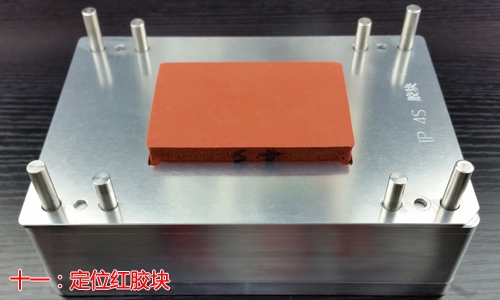

11 . Fix the red gommure |

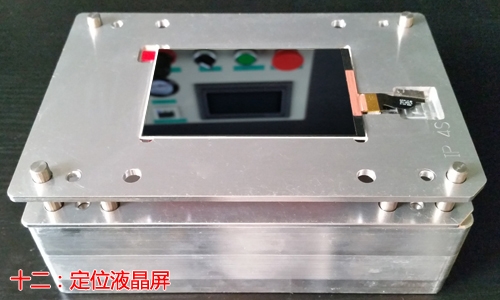

12 . Fix LCD |

|

|

|

|

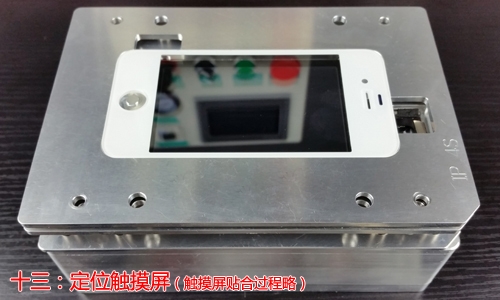

13 . Fix TP (The process of laminating TP is omitted) |

14 . Push into vacuum chamber and then switch the button of laminating LCD |

- This operation only took auto-pattern for example ,you can also choose manual pattern

- Please remember to keep the parameters when setting on LCD

- The red value of inner ring of pressure guage shows pressure value

- The value of vacuum guage is less than or equal to -100 , it means that a complete vacuum state

- Use black gommure to laminate OCA and TP while red gommure to LCD

- The process of laminating TP is omitted

- There is an indentation in every mould , so pay attention to ensure indentations are consistent when laminating