Technical Ariticle

-

21 AprRead more »

First, you must understand that OCA is a special glue, it is softer than solid but harder than liquid LOCA glue, when using LOCA glue to refurbish the LCD we never have air bubbles, this is because air bubbles are easily removed from the liquid, but air cannot easily pass through the colloid. Why there is return bubbles? Do you think that after putting the air bubbles in the autoclave for about 5 minutes, do you actually remove all the air bubbles? The answer is no, the real process of removing the bubbles is to squeeze the air out of the OCA after lamination, maybe you don't see any bubbles after the bubbles are removed, but the fact is that the bubbles have been separated by a lot of tiny bubbles that you can't see with your eyes, but once those tiny bubbles come together after a few minutes or hours, they become tiny bubbles that you can see. How can this be avoided? 1, choose a good quality OCA, Mitsubishi is the most popular glue on the market today, it is very soft

-

8 AprRead more »

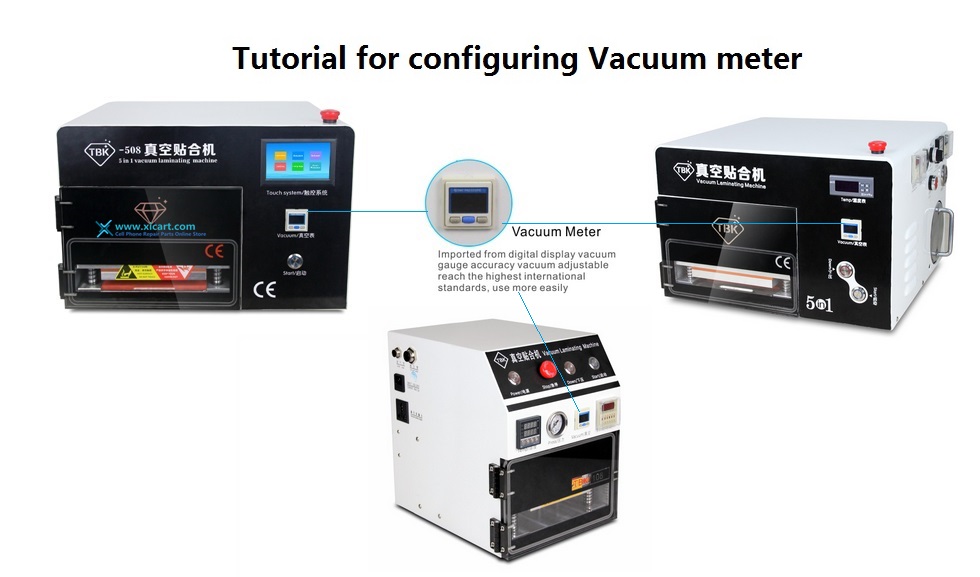

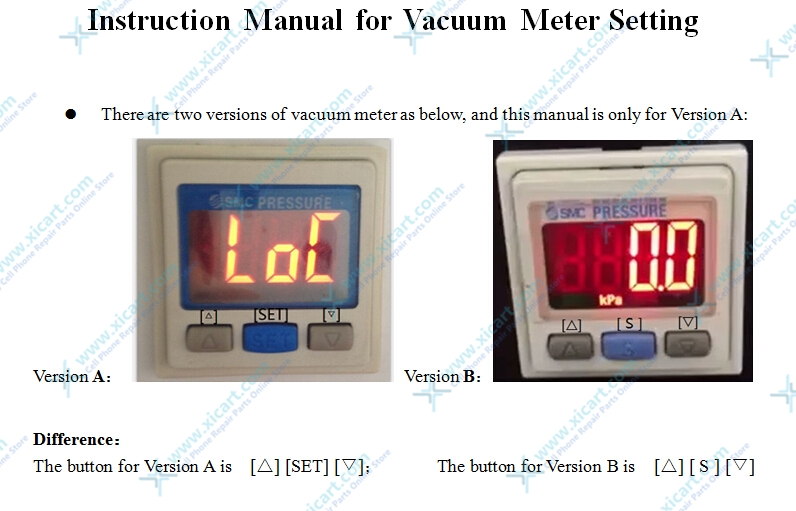

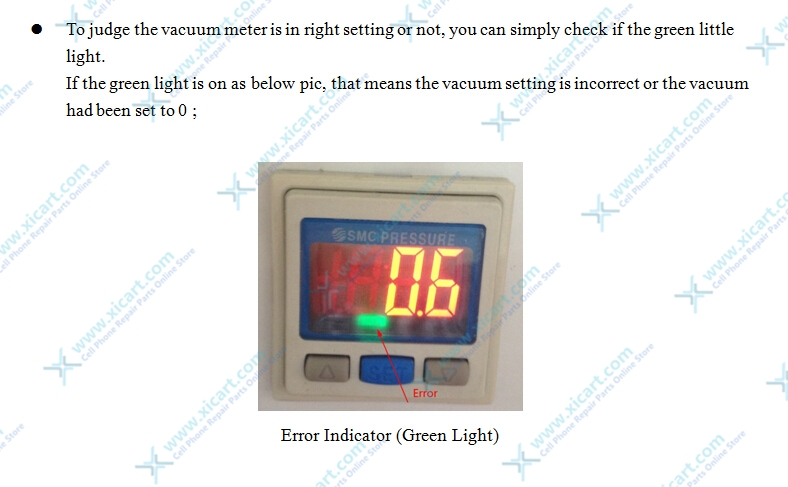

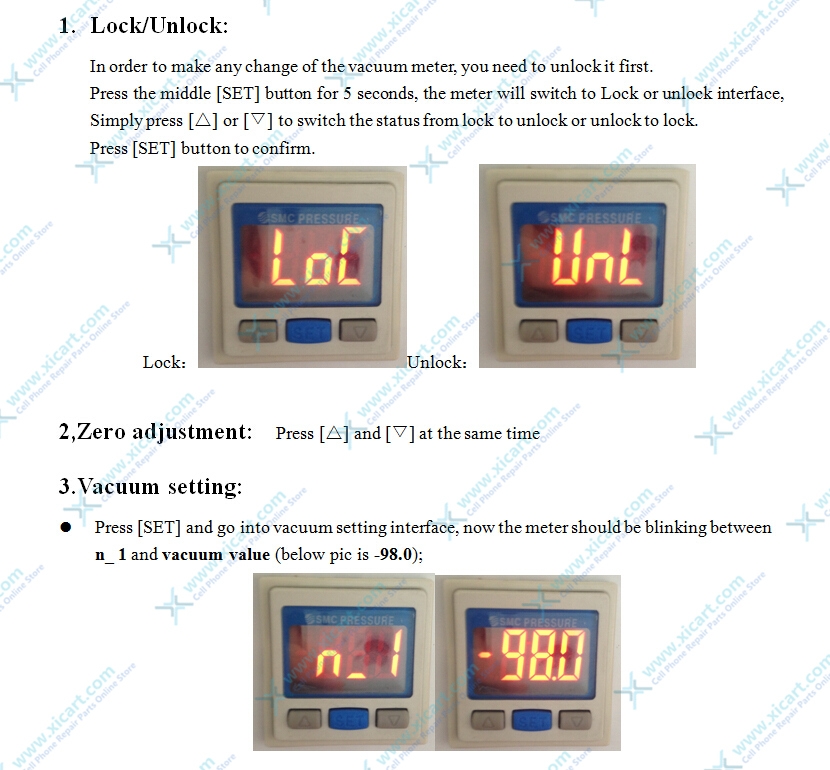

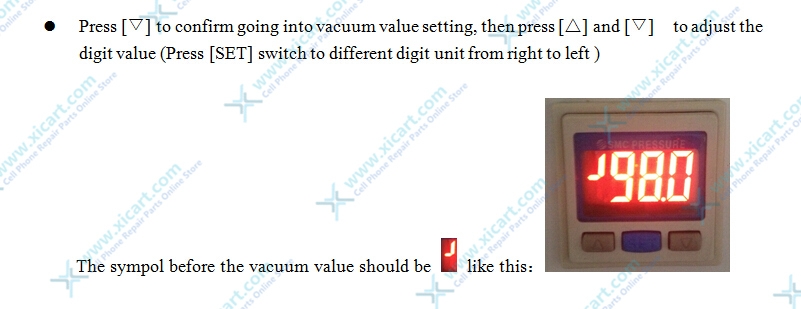

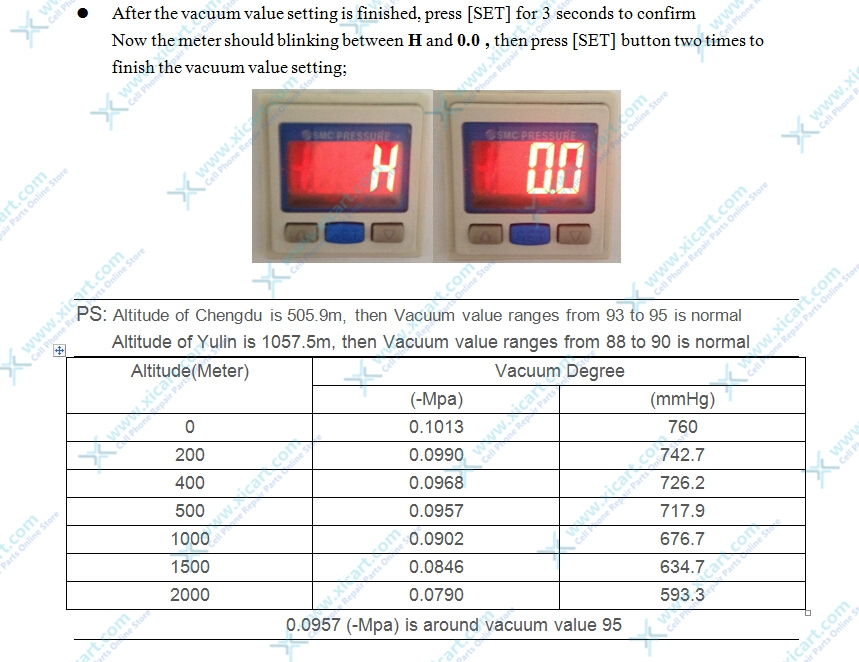

Tutorial-Instruction Manual for Vacuum Meter Setting

-

8 AprRead more »

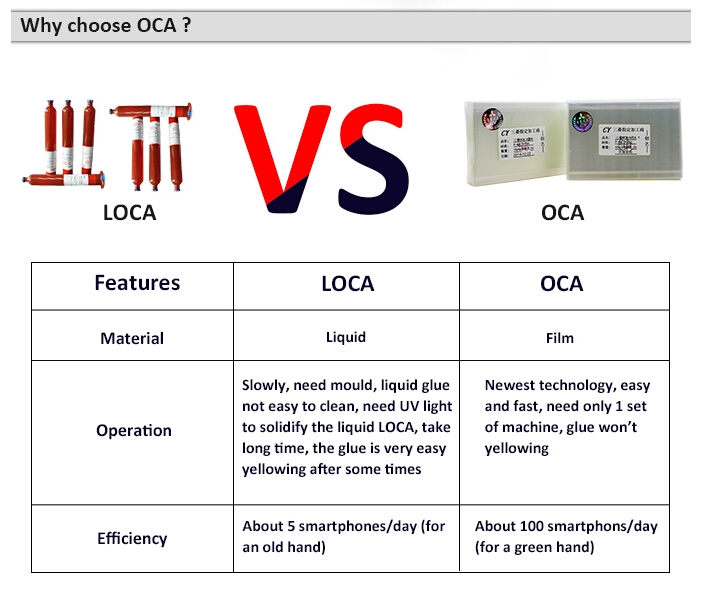

Sometime we have a confusion about LOCA VS OCA, which one of these two is better for us to refurbish a LCD? Here is a brief comparison.

LOCA is a better choice when doing a home replacement! While the OCA is more popular between manufacturers and refurbishing factories, OCA is more professional in some way and it needs specialized equipment. Such as the OCA laminating machine. And this kind of machine is very expensive, if not do a massive repair, it is no need to spend too much to buy the professional equipment! And actually the LOCA is more convenient

-

8 AprRead more »

LCD refurbishing Process of vacuum oca laminating machine

Before the invention of vacuum OCA laminating machine, repair of a LCD broken glass was impossible unless the device was taken back to the factory.

Fortunately, this machine came and now experts can repair and replace an LCD screen without having to replace digitizer (a very complicated operation that can easily fail) or seek the manufacturer’s assistance. This machine comes with five exclusive features; broken glass separating,OCA/LOCA glue removing, OCA glue pasting, high pressure laminating and vacuum bubble

-

8 AprHere we show you 5 tips to tell the difference between an OEM and copy LCD for the iPhone 6.Read more »

-

8 AprChassis Diagram for all the Ipad models...Read more »